Vibration polishing machine Application& Advantage Vibratory tumble finishing systems produce a cutting action by shaking the processing vessel (the finishing tub) at a high speed, causing the tumbling media and parts to scrub against each other. This scrubbing action precisely abrades the parts to remove burrs. A shaft with rotating eccentric weights mounted on the tub produces the shaking action. Vibratory deburring machines and finishing systems produce a cutting action that is very thorough. They remove material from pockets and recesses and inside bores, which cannot be done in a barrel tumbler, so they can be used for very delicate or intricate parts. With high speeds and a short stroke, they can also run large bulky parts without damage. Large wing spans and landing struts are routinely run in these systems. Vibratory finishing systems also lend themselves to be automated easily. They can be fully automated for a flow-through operation or used as a basic batch operation. The action is that of a small orbit at a high speed and thus is very powerful, yet causes little stress on the parts

Different models & Techincal | Model | Capacity | Motor Power | Motor speed | PU | Weight(kg) | Size(L×W×H)mm |

| (r/min) | (mm) |

| HST-60(A) | 60L | 0.75kw | 1450 | 12 | 100 | 700×640×750 |

| HST-80(A) | 80L | 1.1kw | 1450 | 12 | 120 | 860×800×760 |

| HST-100(A) | 100L | 1.5KW | 1450 | 15 | 140 | 1150*1050*950 |

| HST-150(A) | 150L | 2.2kw | 1450 | 20 | 180 | 1170×1100×1000 |

| HST-150(B) | 150L | 2.2kw | 1450 | 20 | 180 | 1170×1100×1000 |

| HST-200(A) | 200L | 2.2kw | 1450 | 20 | 280 | 1480×1350×1100 |

| HST-200(B) | 200L | 2.2kw | 1450 | 20 | 280 | 1480×1350×1100 |

| HST-300(A) | 300L | 3.7kw | 1450 | 20 | 400 | 1480×1350×1100 |

| HST-300(B) | 300L | 3.7kw | 1450 | 20 | 400 | 1480×1350×1100 |

| HST-400(A) | 400L | 3.7kw | 1450 | 20 | 600 | 1480×1350×1100 |

| HST-600(A) | 600L | 5.5-7.5KW | 1450 | 20 | 1500 | 1950×1750×1450 |

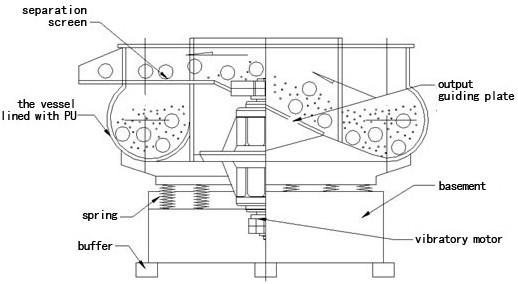

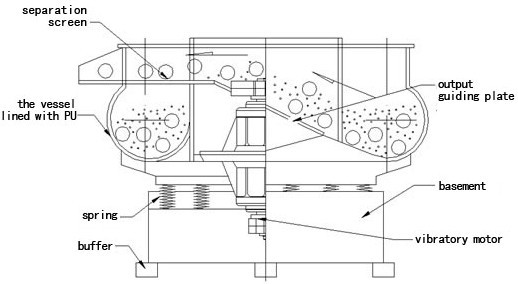

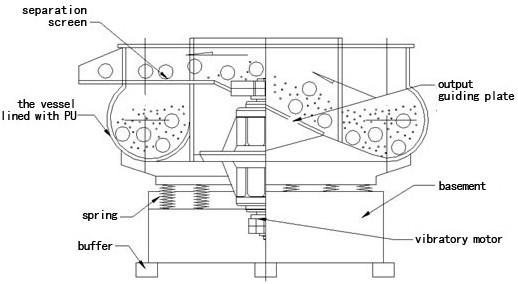

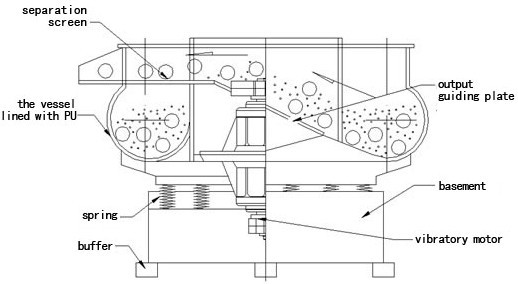

Drawing only for B type

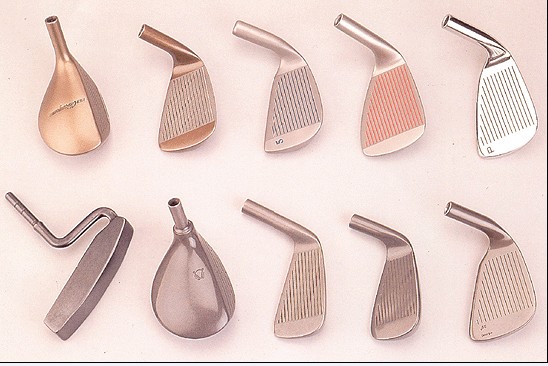

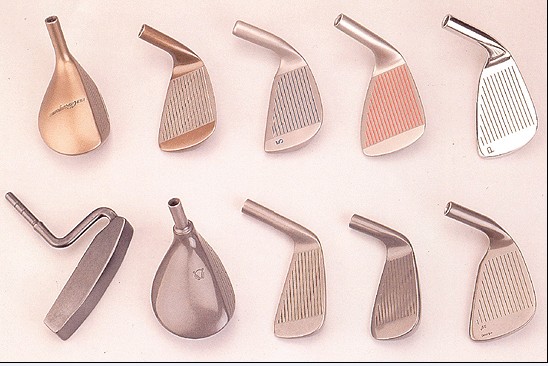

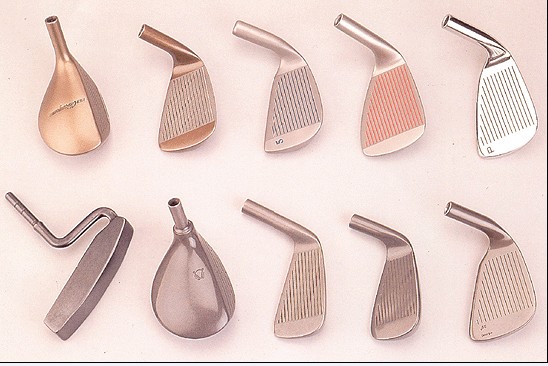

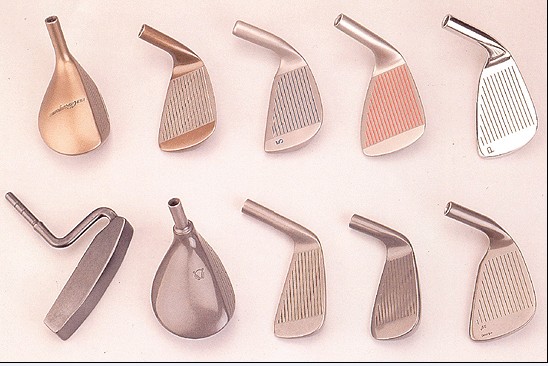

Drawing only for B type Work pieces after be polishing by this machine

Drawing onlyfor B type Work pieces after be polishing by this machine

Drawing onlyfor B type Work pieces after be polishing by this machine

Drawing only for B type Work pieces after be polishing by this machine

Drawing only for B type Work pieces after be polishing by this machine

Drawing onlyfor B type Work pieces after be polishing by this machine

Drawing onlyfor B type Work pieces after be polishing by this machine