Principle of the open blasting machine:

The machine adopts a pressure-feeding type blasting (blasting) mechanism, that is the high-pressure flow of the compressed

air in the high-pressure tank is performed, and the sand in the high-pressure tank is sprayed through the sand pipe

and then the nozzle is compressed by the airflow. High-speed injection onto the surface of the workpiece for sandblasting.

Introduced with advanced German technology.

Adopts the straight-through type blasting valve which completely solves the clogging of the abrasive. The speed of the blasting outlet can reach 200M/S.

| Model | Capacity(L) | Metallic Grit Weight(kg) | Diameter(mm) | Height(mm) | Thickness(mm) | Blasting time(min) |

| HST105P | 150 | 562 | 400 | 1200 | 4.0 | 12 |

| HST106P | 200 | 750 | 500 | 1200 | 5.0 | 18 |

| HST108P | 300 | 1125 | 600 | 1350 | 6.0 | 25 |

| HST108PA | 400 | 1500 | 600 | 1400 | 6.0 | 33 |

| HST108PB | 500 | 1875 | 750 | 1600 | 6.0 | 39 |

| HST109P | 600 | 2250 | 800 | 1550 | 8.0 | 45 |

| HST110P | 1000 | 3750 | 1000 | 1860 | 8.0 | 60 |

| HST120P | 1200 | 4500 | 1200 | 1880 | 8.0 | 70 |

| HST130P | 1600 | 6000 | 1200 | 2030 | 8.0 | 98 |

| HST150P | 2000 | 7500 | 1500 | 2200 | 10.0 | 120 |

| HST180P | 2500 | 9375 | 2000 | 2300 | 12.0 | 160 |

| HST200P | 3000 | 11250 | 2000 | 3000 | 12.0 | 200 |

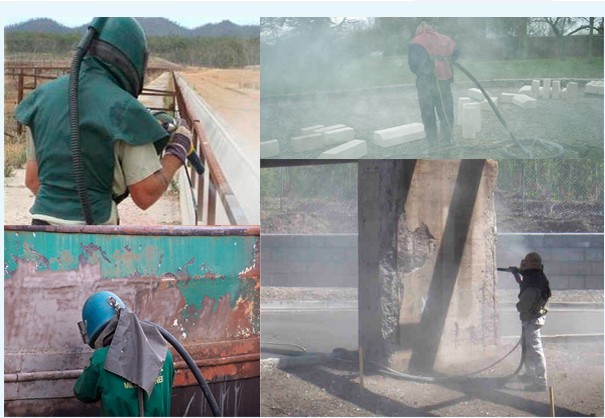

The advantages of the open sand blasting machine:

It can replace the pickling phosphating process and there is no problem of sewage charges. Rapid sandblasting and rust removal

while changing the surface roughness, can also remove the welding slag, burrs, flash. High efficiency

low cost and good quality are unmatched by traditional chemistry and manual descaling. After blasting, the paint quality is good and the coating life is long.

It is a common process adopted internationally.

The sand valve is an important part of the sand blasting machine. Its main function is to control the opening and closing

of the sand material and the stepless adjustment of the sand flow rate during sand blasting. The quality of the sand valve directly affects whether the sand blasting machine can work normally.

Featured Products

-

Sand Blaster Gun Kit Portable Pneumatic Gravity Sandblasting Gun Sandblaster Machine Tools,Remove Surface Rust

-

Vibrabtory tumbler machinery with cover

-

Holdwin Double Work Station Sandblasting Cabinet Manual Sandblaster Equipment Rust Remove Sandblast Machine

-

HOLDWIN Open type sand blasting pot dead man sand blasting machine for steel structure

-

Holdwin Automatic Sandblast Machine Dry Blaster Cabinet Suction Sandblasting Equipment

-

Portable Sandblasting Machine Mobile sandblasting Tank

-

Static Electricity powder making machine 801

-

Sandblasting abrasive Plastic abrasive plastic media, resin media

-

sell well double venturi boron sandblast nozzle for you

-

High quality Boron carbide sandblasting nozzle with PU Jacke

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours