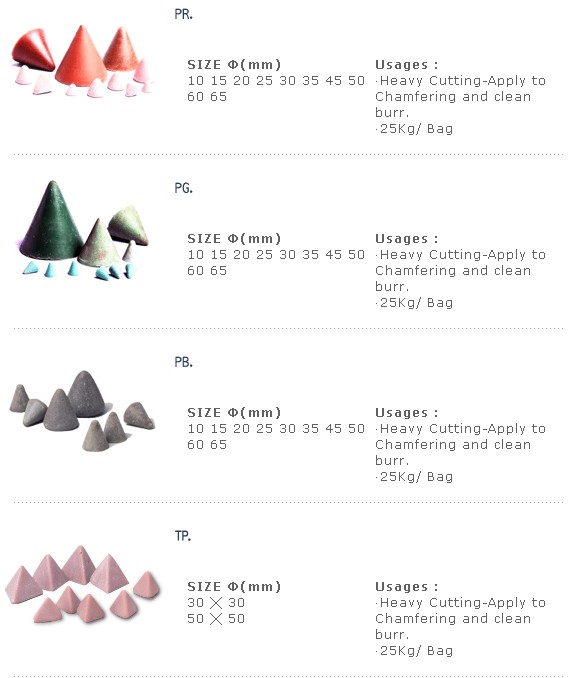

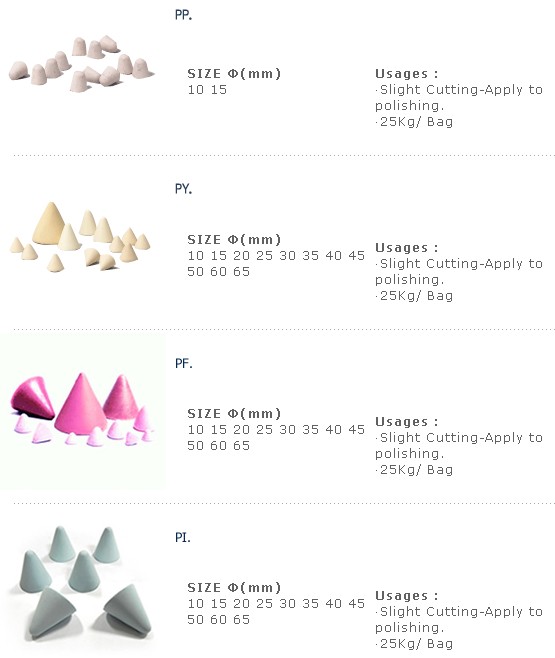

Plastic Mass Finishing Deburring Polishing Media

Features and Application Plastic may seem like an unlikely candidate for tumbling media. However, being about 40% lighter in weight compared to ceramic media, Plastic tumbling media is a lot more convenient to use. Usually, plastic tumbling media is available in cone or pyramid (Tetrahedron) shapes. These shapes effectively prevent workpieces lodging issue that often occurs when using ceramic tumbling media. The lighter weight provides an added advantage when using plastic tumbling media for light metals and acrylics. You can use this media for general purpose metal removal, pre-plate finishing, and moderate cutting It is also considered suitable for brass and aluminum deburring or smoothing plastic parts. You can also use it for secondary surface smoothing of hard metal parts once they have undergone ceramic media deburring. Recently, however, the use of plastic tumbling media has become more common in finishing die casting parts and machined parts, owing to its non-chipping and non-cracking feature. Plus, compared to ceramic media, it offers better surface refinement and inflicts less damage on the metal surface. Thus, you can get metal surfaces ready for electroplating, anodizing, and even painting. The most common shape is cone shape, pyramid shape, triangle shape. Plastic Tumbling Media Feature: * Surface Finish Smoothing * Excellent for Soft Metals * Medium Density Tumbling Media * Light Cutting * Wide Selection of Shapes and Sizes * Short Cycle Times Plastic Tumbling Media Application: * Deburring Brass and Aluminum Parts * Plastic and Rubber Smoothing * Machining Lines Removal * Edge Rounding of Softer Parts * Pre-Plating Finishing