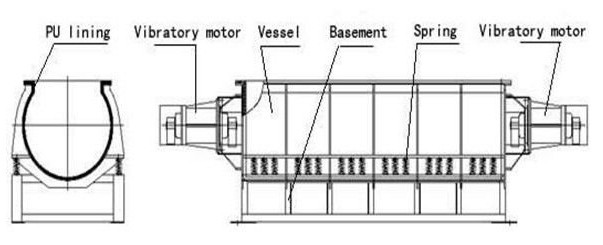

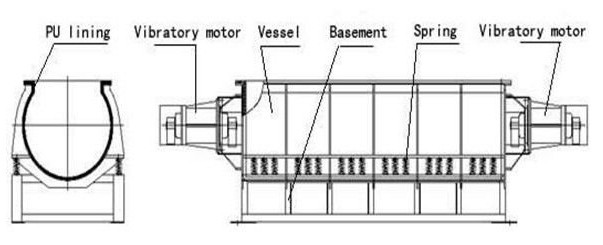

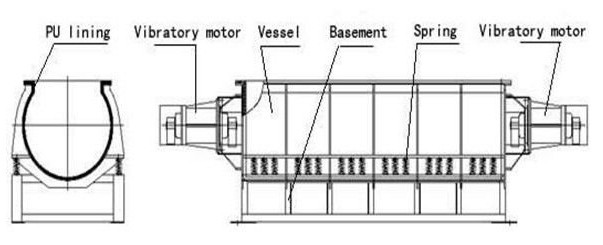

Stone Ageing Trough Vibratory Finishing Machine Product Description: VBS(B) series trough vibratory finishing machines are the well-established solution for finishing heavy and large parts. Besides, the straight wall tub vibrators equipped with fixed or removable polyurethane tub dividers prevent parts contacting. One of the major application of this machine is for marbles tiles aging and antique finishing. With the stone tumbling process, tiles get stone antique treatment look as if it stands 2000 years of time. These antique looking stones are popular at historical buildings. Inovatec uses

variable speed control ensuring optimal tumbling performance. Applications for stone aging finishing includes

columns, granite stone, granitic plate, cliff plate, concrete paving stone, drywall marble stone, calcareous sandstone, sidewalks, sculptures, and mosaic tiles. We are able to process tiles size from

10X10cm to 90X90cm parts with a different model of vibratory tumbling machines. In addition. the Feed-Thu continuous vibratory finishing machine is available for tiles stone production line. Processing time is according to the surface requirement from

15 min-30 min, or longer. This antique treatment process no needs polishing compound. Tap water is enough for lubrication. Inovatec MC ceramic media is ideal for the process. Because of low wearing and higher cutting performance. it is very popular aged stone production, especially in Egypt and Italy.

Technical parameters: | Model | Capacity (L) | Lining thickness (mm) | Empty weight (kg) | Motor (kW) | Tub size (mm) L×W | External dimensions (mm) L×W×H |

| HST240 | 240 | 20 | 450 | 2×1.1 | 690×672 | 1880×880×920 |

| HST500 | 500 | 22 | 1200 | 2×2.2 | 1310×672 | 2870×880×920 |

| HST750 | 750 | 22 | 1600 | 2×5.0 | 2020×672 | 3354×880×920 |

| HST1200 | 1200 | 22 | 2100 | 2×7.0 | 2000×900 | 3000×1150×1120 |