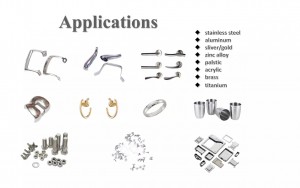

Vibaratory polishing machine Application

The machine is suitable for changeable or beating materials.polishing and screening operation. On the top of this machine, has a turbine access where materials and polishes moving forward to screening section. This process deals with changeable space material and will not hurt material. Screening section equipped with a switch gate and filter screen etc. can separate the grinding tones and materials, easy for operation. The machine is widely used for workpiece surface polishing.chamfering.deburring,derusting. spot removing,fine grinding.

coarse grinding.precision grinding.gloss polishing and vibrating finishing before plating which covers die-casted parts

stamping parts.sheetmetal parts.bicycle parts.furniture hardwares.clothing hardwares.luggage and box hardwares.glasses parts.

medical instruments.bearings.music equipments. Metal fishing tackles.instruments and meters.arts and crafts.daily necessories.

clocks and watches accessories.locks.electronic parts. hand tools(wrench, socket, nozzle etc.) .jewelry.powder metallurgy and resin parts etc.

| Model | Volume | Weight | Motor | Power | Machine Size(mm) | Fill Volume |

| SJ-F100 | 100L | 360kg | 1.5KW | 906*990H | 300kg | |

| SJ-F150 | 150L | 460kg | 2.2KW | 1045*1035H | 380kg | |

| SJ-F200 | 200L | 640kg | 4KW | 1200*1260H | 650kg | |

| SJ-F300 | 300L | 750kg | 5.5KW | 1340*1330H | 950kg | |

| SJ-F400 | 400L | 1070kg | 7.5KW | 1560*1560H | 1200kg | |

| SJ-F600 | 600L | 1660kg | 9KW | 1730*1730H | 2000kg |

Parts which be finished in the Vibratory polishing machine

Below the all kinds of polishing media that suitable for vibratory polishing machine when polishing different workpieces.